What is Injection moulding?

The term "injection moulding" is not familiar to most people. In this article, we are going to find out the answer. Several different types of businesses make use of plastic parts.

Several different types of plastic are used in the construction of vehicles, household goods, and even medical equipment. Yet, only a small percentage of manufacturers are fully aware of the production process for their plastic components.

What is plastic injection moulding?

The technique of injection moulding is one of the most complicated production methods. But it's highly useful for high-volume production. A metal mould is inserted into a specialised hydraulic or electric machine where plastic is melted, injected, and then set.

There are several reasons why plastic injection moulding is the most popular method for producing components in high volume.

Cost-effective

The cost of manufacturing a single unit is minimal, especially when mass quantities are made. However, this is true only after the mould has been constructed. It is the most costly portion of the process.

Quality of plastic parts

The injection moulding process can reliably create high-quality moulded plastic components. The features include the necessary strength, tensile strength, or level of detail that businesses want.

The flexibility of manufacturing plastic

The mould design and thermoplastic used to create each part are up to the manufacturer. Because of this, the injection moulding method can create a wide range of parts. And these include those with intricate designs and plenty of moving elements in high volumes.

The efficiency of injection moulding

The injection moulding machine can create thousands of products per hour after the process has been set up and tested. Energy efficiency is further improved due to the use of electric injection moulding equipment.

Consistency

Injection moulding allows for the rapid, reliable production of thousands of identical parts. It also strictly regulates the variables in the manufacturing process.

What is the procedure for injection moulding?

Injection moulding may seem straightforward at first glance. Nevertheless, it really involves a number of moving parts that must be carefully monitored and managed. Only then can you guarantee the high quality of the final plastic parts.

Manufacturers may choose plastic component manufacturers that can provide the required quality and consistency. But they must have a thorough understanding of the process and the relevant criteria.

The First Step Is to Choose the Correct Thermoplastic and Mold

The correct thermoplastics and moulds must be chosen or made before the real process can begin. And this is because they are the building blocks from which the finished products will emerge.

Manufacturers would be wise to think about the thermoplastic's compatibility with the mould when making their choice. This is due to the fact that certain plastics cannot be used with specific mould configurations.

Components of the mould

The cavity and the core are the two main components of every mould tool. This cavity is a permanent feature into which the plastic is injected. The cavity is used to give the component its final shape. On the other hand, the core is a movable portion that fits into the cavity.

Moulding tools may be made to make simple or intricate parts, so long as the needs are well defined. Moulding tools are often composed of steel or aluminium. These metals get subjected to high pressures and temperatures.

High standards of design and material quality make the process of creating mould tools time-consuming and costly. Thus, tools should be made before the final custom mould is made. Computer-aided design (CAD) software and 3D printing technologies are also required for creating and testing prototypes.

The selected thermoplastic may be tested in the machine once its mould has been digitally developed or created using these technologies.

Testing is critical

The final part's qualities can only be guaranteed if the correct thermoplastic is used in the tool's testing phase. The molecular structure of a thermoplastic determines its properties, melting point, and pressure resistance. Semi-crystalline plastics have a relatively well-ordered molecular structure. On the other hand, amorphous plastics have a more disorganised structure.

The thermoplastic is fed into and melted in step two

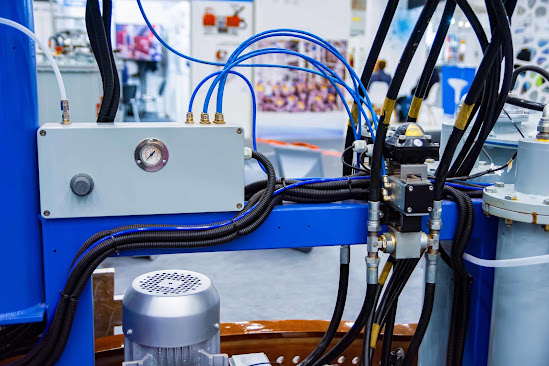

Hydraulic or electrical power may be used to run injection moulding machines. There are significant financial and environmental benefits to switching from hydraulic to electric injection moulding equipment.

These machines are made up of the following components at their most fundamental level:

- A top-mounted feeder, often known as a "hopper," on the machine

- A heated barrel that is long and cylindrical and houses an injection screw of significant size.

- Gate, located at the very tip of the cylinder

- The specific moulding tool that the gate is attached to

Feeding the raw pellets

To begin the process, the desired thermoplastic is first loaded into the machine as raw pellets through the top hopper. These pellets are slowly fed into the machine's barrel while the screw rotates. The thermoplastic is warmed and melted by the barrel's heat and the screw's rotation.

The efficiency of the plastic injection and the precision of the created item depend on keeping the process at the proper temperature.

The third stage is plastic injection moulding

As the hot plastic reaches the end of the barrel, the injection gate shuts and the screw retracts. This increases the pressure inside the screw in preparation for injection by drawing through a certain quantity of plastic.

Simultaneously, tremendous pressure is applied, known as "clamp pressure." And this is to bring the two halves of the mould tool together.

The precise moulding of the item and the prevention of plastic leakage during injection need a delicate balance between injection pressure and clamp pressure. When the appropriate amount of pressure has been applied to the tool and screw, the gate will open. Next, the screw will advance, and the molten plastic will be injected into the mould.

Holding and cooling time constitutes Step 4

The mould is then pressurised for a certain amount of time after the majority of the plastic has been injected into it. Depending on the thermoplastic used and the intricacy of the item, this "holding time" might be anything from milliseconds to minutes. To ensure the plastic packs out of the tool and takes the desired shape, this holding time is essential.

Comments

Post a Comment